1. General

1.1 Air circuit breakers (ACB) shall comply with standards IEC 60 947-1 and -2 or standards derived from the latter; optional version may comply with UL / ANSI / JIS standard.

1.2 The ACB breaking capacity performance certificates shall be available for category B according to IEC 60 947-2 standards. Air circuit breakers shall have a breaking capacity justified by calculations taking into account their installation location. The test shall be carried out with a breaking performance during operation (Ics) and admissible short time withstand (Icw) equal to the ultimate breaking capacity (Icu).

1.3 All Air circuit breakers can be reverse fed without reduction in performance.

1.4 All Air circuit breakers shall have a rated operational voltage of 690V AC (50/60Hz).

1.5 The rated insulation voltage shall be 1000V AC (50/60Hz).

1.6 All circuit breakers shall be fully tropicalized as standard.

1.7 Air circuit breakers shall suitable for isolation according to IEC 60 947-1 and –2 for the rated insulation voltage of 1000 V and for the overvoltage category IV.

1.2 The ACB breaking capacity performance certificates shall be available for category B according to IEC 60 947-2 standards. Air circuit breakers shall have a breaking capacity justified by calculations taking into account their installation location. The test shall be carried out with a breaking performance during operation (Ics) and admissible short time withstand (Icw) equal to the ultimate breaking capacity (Icu).

1.3 All Air circuit breakers can be reverse fed without reduction in performance.

1.4 All Air circuit breakers shall have a rated operational voltage of 690V AC (50/60Hz).

1.5 The rated insulation voltage shall be 1000V AC (50/60Hz).

1.6 All circuit breakers shall be fully tropicalized as standard.

1.7 Air circuit breakers shall suitable for isolation according to IEC 60 947-1 and –2 for the rated insulation voltage of 1000 V and for the overvoltage category IV.

2. Construction

2.1 Environmental aspects

2.1.1 Production site organization shall be certified to comply with ISO 9002 and ISO 14001

standards.

2.1.2 Air circuit breakers shall be supplied in recyclable packing complying with European Directives. The manufacturer shall implement non polluting production processes that do not make use of chlorofluorocarbons, chlorinated hydrocarbons, ink for cardboard markings, etc…

2.1.3 Environmental considerations and processing of materials at end of service life.

The manufacturer shall provide instructions on the removal, dismantling and processing of Air circuit-breaker materials at the end of service life (material composition, weight, toxicity).

standards.

2.1.2 Air circuit breakers shall be supplied in recyclable packing complying with European Directives. The manufacturer shall implement non polluting production processes that do not make use of chlorofluorocarbons, chlorinated hydrocarbons, ink for cardboard markings, etc…

2.1.3 Environmental considerations and processing of materials at end of service life.

The manufacturer shall provide instructions on the removal, dismantling and processing of Air circuit-breaker materials at the end of service life (material composition, weight, toxicity).

2.2 General features

2.2.1 Air circuit breaker shall be designed in such a way that maintenance may be carried out as a function of their use. To reduce maintenance, electrical endurance shall be greater than 10 000 cycles up to 1 600 A, 6 000 cycles up to 2 kA and 1 500 cycles for values greater than 4 kA.

2.2.2 No safety clearance shall be required around drawout circuit breakers. For fixed circuit breakers, 150 mm of free space shall be provided above the arc chutes to allow removal of the latter.

2.2.3 The operating mechanism shall be of the Open/Closed/Open stored-energy spring type. The closing time shall be less than or equal to 70 milliseconds.

2.2.4 Air circuit breakers main contact shall be encased in a reinforced polyester casing and offer double insulation from the operators on the breaker front face.

2.2.2 No safety clearance shall be required around drawout circuit breakers. For fixed circuit breakers, 150 mm of free space shall be provided above the arc chutes to allow removal of the latter.

2.2.3 The operating mechanism shall be of the Open/Closed/Open stored-energy spring type. The closing time shall be less than or equal to 70 milliseconds.

2.2.4 Air circuit breakers main contact shall be encased in a reinforced polyester casing and offer double insulation from the operators on the breaker front face.

2.3 Main contacts

2.3.1 The main contacts shall be designed such that no maintenance shall be required under normal conditions of use.

2.3.2 The main contacts shall be equipped with a visual wear indicator that may be accessed by removing the arc chutes, for immediate assessment of contact wear without requiring measurements or specific tools.

2.3.2 The main contacts shall be equipped with a visual wear indicator that may be accessed by removing the arc chutes, for immediate assessment of contact wear without requiring measurements or specific tools.

2.4 Arc chutes

2.4.1 The arc chutes shall be removable on site.

2.4.1 Air circuit breakers shall be equipped with metal filters to reduce effects perceptible from the outside during current interruption.

2.4.1 Air circuit breakers shall be equipped with metal filters to reduce effects perceptible from the outside during current interruption.

2.5 Drawout mechanism

The drawout operation shall be possible through a closed door. Three positions of the moving part shall be possible:

1 – Connected position – all auxiliary and main circuits engaged

2 – Test position – all auxiliary circuits engaged all main circuits disconnected

3 – Isolated position – all circuits disconnected.

1 – Connected position – all auxiliary and main circuits engaged

2 – Test position – all auxiliary circuits engaged all main circuits disconnected

3 – Isolated position – all circuits disconnected.

2.6 Safety requirements

2.6.1 A door interlock shall be provided so that it shall not be possible to open the door until the air circuit breaker moving part is in the disconnected position.

2.6.2 Insulated safety shutters shall be provided over the incoming and outgoing main circuits and over the auxiliary circuits. An interlocking shall be provided to prevent insertion of a circuit breaker having a rating higher than the current rating of the fixed part, into that fixed part.

2.6.3 The racking handle shall be stowed on the air circuit breaker in such a manner as to be accessible without defeating the door interlocking.

2.6.2 Insulated safety shutters shall be provided over the incoming and outgoing main circuits and over the auxiliary circuits. An interlocking shall be provided to prevent insertion of a circuit breaker having a rating higher than the current rating of the fixed part, into that fixed part.

2.6.3 The racking handle shall be stowed on the air circuit breaker in such a manner as to be accessible without defeating the door interlocking.

2.7 Electrical auxiliaries

2.7.1 All electrical auxiliaries including the motor spring charging mechanism shall be field adaptable without adjustment or the necessity for any tool (except a screwdriver). They shall be fitted into a compartment which under normally loaded conditions has no metalwork energized from the main poles exposed with it. Any adaptation carried out thus shall not increase the breaker volume.

2.7.2 It shall be possible to connect all auxiliary wiring from the front face of the air circuit breaker, this wiring shall be taken through a set of disconnecting contacts, so that all auxiliary wiring is automatically disconnected in the isolated position.

2.7.2 It shall be possible to connect all auxiliary wiring from the front face of the air circuit breaker, this wiring shall be taken through a set of disconnecting contacts, so that all auxiliary wiring is automatically disconnected in the isolated position.

2.8 Mechanical indicators

Mechanical indicators on the front panel of Air circuit breakers shall indicate the following status conditions:

1. “ON” (main contacts closed) Spring charged

2. “ON” (main contacts closed) Spring discharged

3. “OFF” (main contacts open) Spring charged – circuit breaker ready to close

4. “OFF” (main contacts open) Spring charged – circuit breaker not ready to close

5. “OFF” (main contacts open) Spring discharged

1. “ON” (main contacts closed) Spring charged

2. “ON” (main contacts closed) Spring discharged

3. “OFF” (main contacts open) Spring charged – circuit breaker ready to close

4. “OFF” (main contacts open) Spring charged – circuit breaker not ready to close

5. “OFF” (main contacts open) Spring discharged

3. Over current Protection (Digital Control Unit for general application)

3.1 General

The ACB control unit shall be interchangeable on site for adaptation to changes in the installation. Sensors shall be non-magnetic or of the Rogowski type for accurate current measurements up to Ics value. The ACB control unit shall measure the true rms value of the current. The ACB control unit shall comprise a thermal memory to store temperature-rise data in the event of repeated overloads or earth faults.

3.2 Protection

3.2.1 The ACB control unit shall offer the following protection functions as standard:

3.2.1.1 Long-time (LT) protection with an adjustable current setting and time delay;

3.2.1.2 Short-time (ST) protection with an adjustable pick-up and time delay;

3.2.1.3 Instantaneous (INST) protection with an adjustable pick-up and an OFF position.

3.2.1.1 Long-time (LT) protection with an adjustable current setting and time delay;

3.2.1.2 Short-time (ST) protection with an adjustable pick-up and time delay;

3.2.1.3 Instantaneous (INST) protection with an adjustable pick-up and an OFF position.

3.2.2 Current and time-delay settings shall be indicated in amperes and seconds respectively on a digital display.

3.2.3 Earth-fault protection with an adjustable pick-up and time delay shall be provided if indicated on the appended single-line diagram.

3.2.3 Earth-fault protection with an adjustable pick-up and time delay shall be provided if indicated on the appended single-line diagram.

3.3 Measurements

3.3.1 An ammeter with a digital display shall indicate the true rms values of the currents for each phase.

3.3.2 A LED bar graph shall simultaneously display the load level on the three phases.

3.3.3 A maximeter shall store in memory and display the maximum current value observed since the last reset. The data shall continue to be stored and displayed even after opening of the circuit breaker.

3.3.2 A LED bar graph shall simultaneously display the load level on the three phases.

3.3.3 A maximeter shall store in memory and display the maximum current value observed since the last reset. The data shall continue to be stored and displayed even after opening of the circuit breaker.

3.4 Maintenance

3.4.1 The last ten trips and alarms shall be stored in two registers that may be consulted locally (date and time, type of fault or alarm).

3.4.2 Maintenance indicators shall be displayable on request on the front panel:

3.4.2.1 Contact wear

3.4.2.2 Operations counter.

3.4.2 Maintenance indicators shall be displayable on request on the front panel:

3.4.2.1 Contact wear

3.4.2.2 Operations counter.

3.5 Communication option

3.5.1 On option Air Circuit Breaker shall be capable of communicating the following data via a bus:

3.5.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

3.5.1.2 Control-unit settings;

3.5.1.3 Tripping causes;

3.5.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

3.5.2 It shall be possible to remotely control the circuit breaker.

3.5.3 It shall be possible to remotely modify circuit-breaker settings:

3.5.3.1 Settings within the range defined by the switches on the front panel of the control unit;

3.5.3.2 Settings of the protection functions and the alarms.

3.5.4 Communications functions shall be independent of the control unit.

3.5.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

3.5.1.2 Control-unit settings;

3.5.1.3 Tripping causes;

3.5.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

3.5.2 It shall be possible to remotely control the circuit breaker.

3.5.3 It shall be possible to remotely modify circuit-breaker settings:

3.5.3.1 Settings within the range defined by the switches on the front panel of the control unit;

3.5.3.2 Settings of the protection functions and the alarms.

3.5.4 Communications functions shall be independent of the control unit.

4. Over current Protection (Digital Control Unit for general application with Energy and Power Measurements)

4.1 General

The ACB control unit shall be interchangeable on site for adaptation to changes in the installation. Sensors shall be non-magnetic or of the Rogowski type for accurate current measurements up to Ics value. The ACB control unit shall measure the true rms value of the current. The ACB control unit shall comprise a thermal memory to store temperature-rise data in the event of repeated overloads or earth faults.

4.2 Protection

4.2.1 The ACB control unit shall offer the following protection functions as standard:

4.2.1.1 Long-time (LT) protection with an adjustable current setting and time delay;

4.2.1.2 Short-time (ST) protection with an adjustable pick-up and time delay;

4.2.1.3 Instantaneous (INST) protection with an adjustable pick-up and an OFF position.

4.2.2 And time-delay settings shall be indicated in amperes and seconds respectively on a digital display

4.2.1.1 Long-time (LT) protection with an adjustable current setting and time delay;

4.2.1.2 Short-time (ST) protection with an adjustable pick-up and time delay;

4.2.1.3 Instantaneous (INST) protection with an adjustable pick-up and an OFF position.

4.2.2 And time-delay settings shall be indicated in amperes and seconds respectively on a digital display

4.2.3 Earth-fault protection with an adjustable pick-up and time delay shall be provided if indicated on the appended single-line diagram.

4.3 Additional protection functions

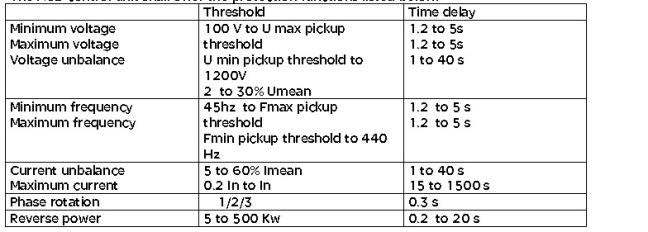

The ACB control unit shall offer the protection functions listed below.

4.4 Maintenance

4.4.1 The last ten trips and alarms shall be stored in two registers that may be consulted locally (date and time, type of fault or alarm).

4.4.2 Maintenance indicators shall be displayable on request on the front panel:

4.4.2.1 Contact wear

4.4.2.1 Operations counter.

4.4.2 Maintenance indicators shall be displayable on request on the front panel:

4.4.2.1 Contact wear

4.4.2.1 Operations counter.

4.5 Communication option

4.5.1 On option Air Circuit Breaker shall be capable of communicating the following data via a bus:

4.5.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

4.5.1.2 Control-unit settings;

4.5.1.3 Tripping causes;

4.5.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

4.5.2 It shall be possible to remotely control the circuit breaker.

4.5.3 It shall be possible to remotely modify circuit-breaker settings:

4.5.3.1 Settings within the range defined by the switches on the front panel of the control unit;

4.5.3.1 Settings of the protection functions and the alarms.

4.5.4 Communications functions shall be independent of the control unit

4.5.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

4.5.1.2 Control-unit settings;

4.5.1.3 Tripping causes;

4.5.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

4.5.2 It shall be possible to remotely control the circuit breaker.

4.5.3 It shall be possible to remotely modify circuit-breaker settings:

4.5.3.1 Settings within the range defined by the switches on the front panel of the control unit;

4.5.3.1 Settings of the protection functions and the alarms.

4.5.4 Communications functions shall be independent of the control unit

5. Measurements (Digital Control Unit for general application with Energy and Power

Measurments)

An ammeter with a digital display shall indicate the true rms values of the currents for each phase. A LED bargraph shall simultaneously display the load level on the three phases. A maximeter shall store in memory and display the maximum current value observed since the last reset. The data shall continue to be stored and displayed even after opening of the circuit breaker.

5.1 Power measurements

5.1.1 The ACB control unit shall measure voltages and calculate power and energy values.

5.1.1 These values shall be displayable on the screen and updated every second. The minimum and maximum values shall be stored in memory.

5.1.1 These values shall be displayable on the screen and updated every second. The minimum and maximum values shall be stored in memory.

Accuracy

Energy (kWh) :2 %

Real power (kW) :2 %

Apparent power (kVA) :2 %

Demand power (kWh) :2 %

Energy (kWh) :2 %

Real power (kW) :2 %

Apparent power (kVA) :2 %

Demand power (kWh) :2 %

5.2 Measurement of power quality

5.2.1 The control unit shall offer functions allowing the analysis of the quality of AC distribution system power, including:

5.2.1.1 Measurement of the amplitude and phase of current and voltage harmonics up to the 31st order;

5.2.1.2 Measurement of the fundamental components of the voltage, current, active power, reactive power and apparent power;

5.2.1.3 Measurement of total current and voltage harmonic distortion.

5.2.1.1 Measurement of the amplitude and phase of current and voltage harmonics up to the 31st order;

5.2.1.2 Measurement of the fundamental components of the voltage, current, active power, reactive power and apparent power;

5.2.1.3 Measurement of total current and voltage harmonic distortion.

5.3 Maintenance

5.3.1 The last ten trips and alarms shall be stored in two registers that may be consulted locally (date and time, type of fault or alarm).

5.3.2 Maintenance indicators shall be displayable on request on the front panel:

5.3.2.1 Contact wear

5.3.2.2 Operations counter

5.3.2 Maintenance indicators shall be displayable on request on the front panel:

5.3.2.1 Contact wear

5.3.2.2 Operations counter

5.4 Communication option

5.4.1 On option Air Circuit Breaker shall be capable of communicating the following data via a bus:

5.4.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

5.4.1.2 Control-unit settings;

5.4.1.3 Tripping causes;

5.4.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

5.4.2 It shall be possible to remotely control the circuit breaker.

5.4.3 It shall be possible to remotely modify circuit-breaker settings:

5.4.3.1 Settings within the range defined by the switches on the front panel of the control unit;

5.4.3.2 Settings of the protection functions and the alarms.

5.4.4 Communications functions shall be independent of the control unit

5.4.1.1 Circuit-breaker status (open/closed, connected/disconnected/test, tripped on a fault, ready to close);

5.4.1.2 Control-unit settings;

5.4.1.3 Tripping causes;

5.4.1.4 The measurements processed by the control unit: current, voltage, frequency, power, power quality.

5.4.2 It shall be possible to remotely control the circuit breaker.

5.4.3 It shall be possible to remotely modify circuit-breaker settings:

5.4.3.1 Settings within the range defined by the switches on the front panel of the control unit;

5.4.3.2 Settings of the protection functions and the alarms.

5.4.4 Communications functions shall be independent of the control unit